Path to a Greener Tomorrow── Chyi Yang's CFV Solutions of Precision and Sustainability

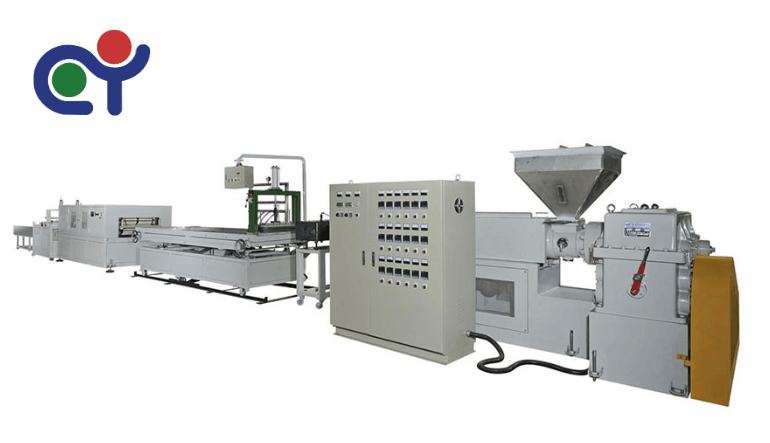

Global environmental awareness has prompted the manufacturing industry to transition towards green production. The need for "carbon reduction" in the CFV stages has led the global blown film manufacturing industry to pursue sustainable development solutions. Chyi Yang's 5-layer / 7-layer co-extrusion blown film machines have become a key player in today's green supply chain due to their three key advantages: "Big Data Analysis," "Precision Formulation and Calculation Functions," and "Recycled Waste Technology Innovations" in their multi-layer blown film machines. The international blown film manufacturing market also recognizes the indispensability of Chyi Yang in the trend of carbon reduction.

CHYI YANG: Transforming Waste into Gold, ABA Co-extrusion Machine Revolutionized Bag Manufacturing

The unique die head design of the ABA co-extrusion machines offers producers cost management flexibility by incorporating an middle layer of recycled material or calcium carbonate compound, effectively reducing raw material expenses. This not only maintains competitiveness in raw material prices but also aligns with environmental trends.

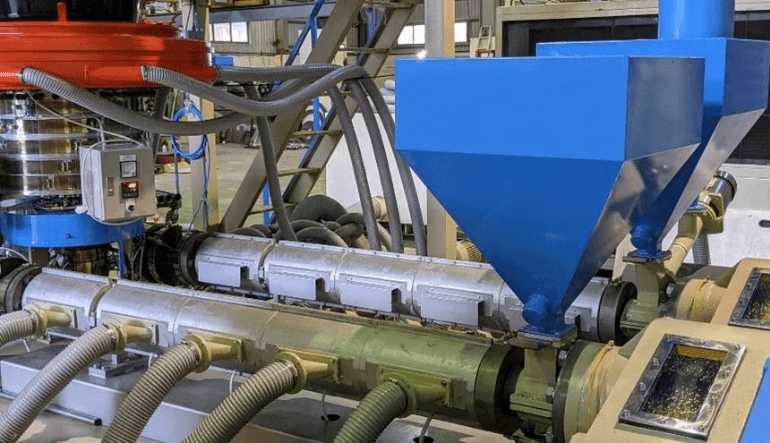

FIMIC Innovations in Automatic Filtration

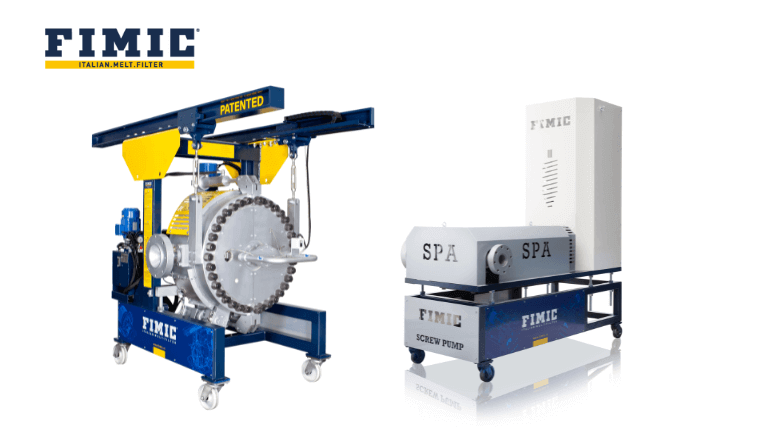

Recycling is a game where size matters. Nowadays recyclers need to reach a higher hourly production capacity with efficiency and simplicity, they required right applications for high-throughput recycling lines. FIMIC has been working many years now on improving its filtration technologies in order to meet and satisfy the needs (quality, characteristics) of recyclers, and at the same time facing the challenges of recycling post-consumer and post-industrial plastics.

FIMIC at NPE 2024

NPE2024 in Orlando is approaching fast after 6 years of waiting, and preparations are in full swing. FIMIC is returning for the third time to NPE with an array of exciting updates, since 2018 FIMIC has developed technologies offering a wide range of automatic melt filters and has integrated into their product portfolio a screw pump called SPA, available in three different sizes to easily transport the plastic melt without using gears that can be positioned before or after the filter. At NPE2024, FIMIC will display its flagship melt filter, RAS 700 model, showing plastics industry insiders and all other visitors how its technology can be adapted to the application requirements and is designed precisely for filtration processes.

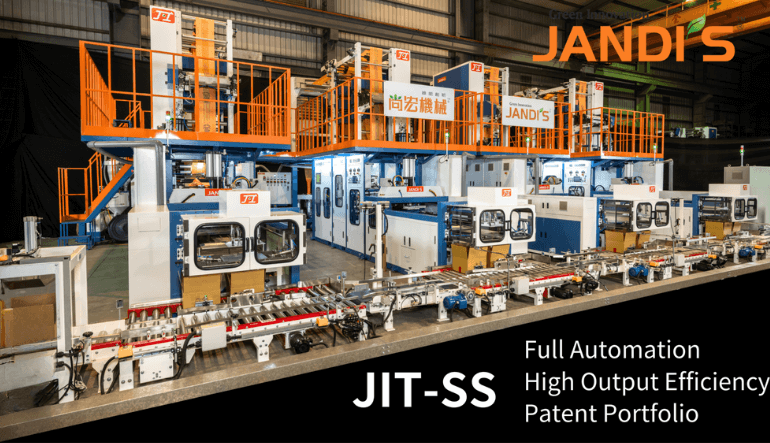

Visit JANDI’S to See the Latest Green Innovation!

Cassava Bag Production : Cassava bag is 100% biodegradable & compostable, also water-dissolved. JANDI’S is working with Avani to offer a Turn-Key Project for production of Cassava bags, including the material supply, marketing strategy, machinery, training and operation skills.

Full Shine Machinery's Expertise in PC Water Bottles Making Machine

Full Shine Machinery has 30 years of experience specializing in Automatic Blow Molding Machines, Multi-layer Co-extrusion Blow Molding Machines (2-6 layers bottle), Accumulator-head Blow Molding Machines, One Stage Injection Blow Molding Machines, and PET Stretch Blow Molding Machines. In addition, we have experience with Molds, Die Heads, and Auxiliary Equipment. Please contact us to learn more about our capabilities.

Daisaku Co., Ltd. and POLYSTAR Collaborate to Lead Japan's Plastic Waste Recycling Industry

DAISAKU CO., LTD, located in Ibaraki Prefecture, Japan, is a leading enterprise in the plastic waste recycling industry. We have been collaborating with POLYSTAR since 2019 to enhance our plastic recycling business. Our partnership with POLYSTAR includes the purchase of their Repro-Flex 150 recycling machine to process various HDPE/LDPE/LLDPE packaging film/bale film/shrink film waste.

WPC PROFILE EXTRUSION MACHINES - 6 KEY FACTORS

Investing in WPC profile extrusion machines is a crucial decision that can significantly impact your production capabilities. However, with so many options available in the market, selecting the right machine that fits your business needs can be a daunting task. To help you make an informed decision, we have put together a comprehensive guide outlining 6 key factors that you need to consider when selecting WPC profile extrusion machines. In this guide, we will cover everything from material compatibility to output requirements, giving you a clear understanding of what to look for in a machine. By the end of this guide, you will have all the necessary information to choose a machine that maximizes your production efficiency, quality, and profitability. So, keep reading to learn more and make an informed decision that will benefit your business.

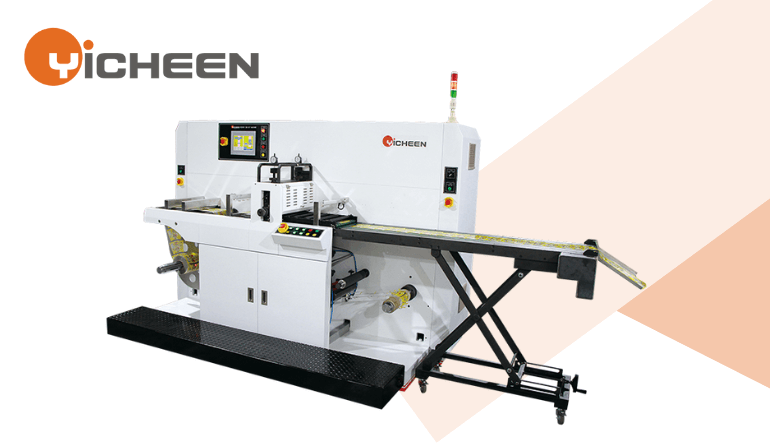

YICHEEN: The Importance of Label Die Cutting Machines

If you want to make the most out of your label converting machines, it is important that you understand how it works. There are two main types of label die-cutting machines for label converting : rotary and flatbed. The best way to learn more about label converting is by talking with experts who have experience designing specific applications. YICHEEN is one of the leading label die cutting machine manufacturers.

Revolutionizing the Market: Chyi Yang's Smart 5/7-layer Blown Film Machines Lead the ESG Sustainability Trend

Chyi Yang's Smart 5/7-layer Blown Film Machines revolutionize plastic film production, reducing costs and material waste while complying with regulations. Their Auto-recycling blown film machines use precision formula calculations and advanced recycling mechanisms to improve production yield and achieve "ZERO WASTE" while reducing energy consumption to improve competitiveness.

GUIDE TO BLOWN FILM EXTRUSION MACHINES

The process to produce the film is similar to blowing bubbles. The blown film machine virtually replicates the blowing process on its tower-like production line except it uses polymers (plastic materials) to replace soap water and nip the continuously blown bubble into an extremely thin film. The tower structure ranges several stages high. After the film is formed, it is wound into rolls and later distributed for final applications. As one of the leading blown film extrusion machine manufacturers with over 50-year-experience in Taiwan, now CHYI YANG is going to break down the process into details and discuss how blown film extrusion works.

Recycling Materials with POLYSTAR for New End Product Possibilities

With consumers increasingly pushing for less raw material usage, the last few years have exhibited an increase in recycled plastics as basic materials for production, helping repurpose products that otherwise would be considered waste. But what type of plastic materials can be recycled? How can plastics be recycled? And what end products can be made using recycled materials?